Description

- Covers Cat 950 Wheel Loader

- 407 pages

- Instant PDF Download

- Bookmarked, searchable, printable

- Compatible with Windows/Mac/Tablet

Covers Serial Numbers 31K962-UP, 43J2724-UP, 73J2081-UP, 81J3730-UP,

This manual covers specifications, systems operation, testing/adjusting and disassembly of the of the Caterpillar 950 Wheel Loader. It includes detailed OEM specs, illustrations and service procedures to guide the mechanic with correctly servicing, overhauling and troubleshooting the machine to the manufacturer’s specifications. The Specifications Manual, Systems Operation Manual, Troubleshooting Manual, Disassembly and Assembly Manual for the systems listed below are included in one convenient downloadable PDF file.

Contents:

Cat 950 Loader Engine Disassembly and Assembly

Cat 950 Loader Disassembly and Assembly

- Brake Chambers, Disassemble & Assemble

- Brake Control Valves

- Brake Control Valves, Disassemble & Assemble

- Brake Master Cylinders and Chambers

- Brake Master Cylinders, Disassemble & Assemble

- Bucket

- Bucket Positioner

- Bucket Positioner Master Cylinder

- Bucket Positioner Master Cylinder, Disassemble & Assemble

- Emergency and Parking Brake Control Valve

- Hydraulic Pump

- Hydraulic Pump, Disassemble & Assemble

- Hydraulic Filter Housing

- Lift Arms and Bucket

- Lift and Tilt Cylinder Bearings

- Lift and Tilt Control Valve

- Lift and Tilt Control Valve, Disassemble & Assemble

- Lift Cylinders

- Lift Cylinders, Disassemble & Assemble

- Lower Pivot Pin Bearings

- Main Frames, Separation & Connection

- Parking Brake Air Chamber

- Parking Brake Air Chamber, Disassemble & Assemble

- Tilt Cylinders

- Tilt Cylinders, Disassemble & Assemble

- Steering Cylinders

- Steering Cylinders, Disassemble & Assemble

- Steering Gear

- Steering Gear, Disassemble & Assemble

- Steering Valve

- Steering Valve, Disassemble & Assemble

- Steering Wheel

- Supplemental Steering Diverter Valve

- Supplemental Steering Diverter Valve, Disassemble & Assemble

- Supplemental Steering Pump

- Supplemental Steering Pump, Disassemble & Assemble

Cat 950 Loader Hydraulic System Specifications

Cat 950 Loader Hydraulic System Systems Operation

- Loader Hydraulic System

- Bucket Positioner Hydraulic Circuit

- Check Valves

- Lift Kickout Hydraulic Circuit

- Main Pressure Relief Valve

- Make-Up Valves

- Tilt Circuit Relief Valves

- Tilt and Lift Control Valve

Cat 950 Loader Hydraulic System Testing & Adjusting

- Loader Hydraulic System

- Schematic

- Bucket Positioner and Lift Kickout Circuits

- Bleeding the Bucket Positioner and Lift Kickout Circuits

- Bucket Positioner Circuit

- Bucket Positioner Cam Lever and Cam Spring Adjustments

- Bucket Positioner Master Cylinder Piston Stroke Adjustment and Bucket Digging Angle Adjustment

- Bucket Positioner and Lift Kickout Master Cylinder Relief Valve Settings

- Lift Kickout Cam Lever and Cam Spring Adjustment

- Lift Kickout Circuit

- Lift Kickout Master Cylinder Piston Stroke Adjustment and Kickout Height Adjustment

- Loader System Test Procedures

- Checking Pump Efficiency

- Lift Circuit Drift

- Lift and Tilt Circuit Speeds

- Tilt Circuit Drift

- Main Pressure Relief Valve and Tilt Circuit Relief Valve

- Testing the Main Pressure Relief Valve

- Testing the Tilt Circuit Relief Valve (Head Ends)

- Testing the Tilt Circuit Relief Valve (Rod Ends)

- Operational Checks

- Visual Checks

Cat 950 Loader Powertrain Specifications

Cat 950 Loader Powertrain Disassembly and Assembly

- Differential and Carrier Assembly

- Drive Axles

- Engine from Torque Converter and Transmission, Separation & Connection

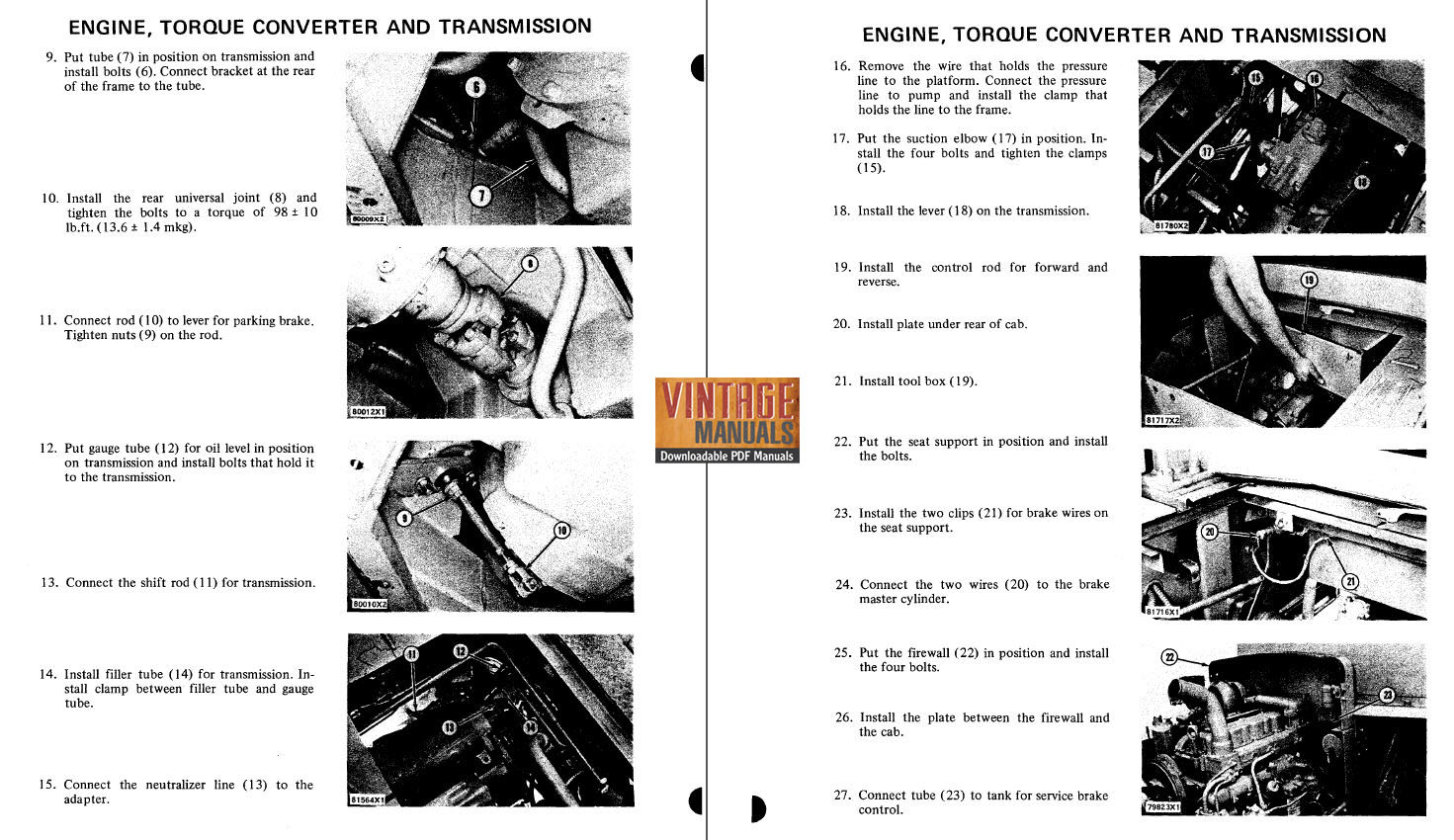

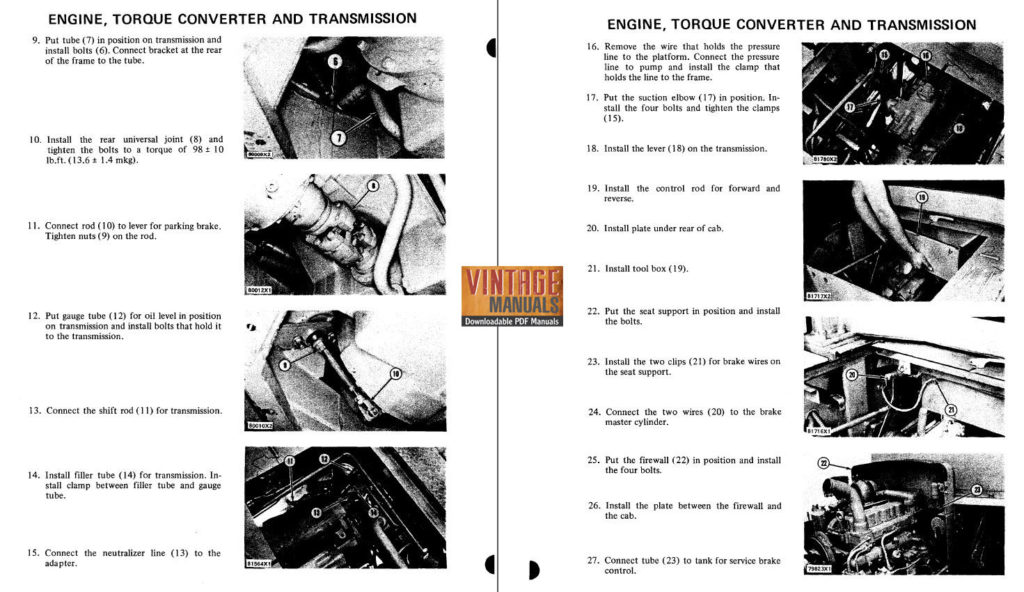

- Engine, Torque Converter and Transmission

- Final Drive

- Final Drive, Disassemble & Assemble

- Final Drive Duo-Cone Seals

- Front Drive Shaft and Support Bearing

- Front Differential

- Parking Brake

- Rear Differential

- Tires and Rims

- Torque Converter, Disassemble & Assemble

- Torque Converter from Transmission, Separation and Connection

- Torque Proportioning Differential and Carrier Assembly, Disassemble & Assemble

- Transmission, Disassemble & Assemble

- Transmission Lubrication Relief Valve

- Transmission Lubrication Relief Valve, Disassemble & Assemble

- Transmission Oil Pump

- Wheels

- Wheel Brakes

- Wheel Brakes, Disassemble & Assemble

- Wheel Brake Discs

- Wheel Brake Linings

- Wheel Spindles

Cat 950 Loader Powertrain Systems Operation

- Differential and Final Drive

- Differential

- Final Drive

- General Information

- Torque Converter and Transmission

- Planetary Transmission

- Torque Converter

- Torque Proportioning Differential

- Transmission Hydraulic Controls

- Transmission Lubrication System

Cat 950 Loader Powertrain Testing & Adjusting

Cat 950 Loader Steering Systems Operation

- Flow of Oil in Neutral Position

- Flow of Oil in Right Turn Position

- Operation of Follow-Up Linkage

- Operation of Relief Valve

- Steering Hydraulic System

Cat 950 Loader Steering Testing & Adjusting

- Instrumentation Tests

- Checking Centered Turning Angle

- Checking Frame Stop Clearance

- Checking Pump Efficiency

- Checking Steering Speed

- Follow-Up Linkage Adjustment

- Steering Gear Adjustment

- Testing Cylinder Pressure Balance

- Testing Pressure Relief Valve

- Operational Checks

- Checking Steering Effort

- Steering Hydraulic System

- Visual Checks

Cat 950 Loader Steering Specifications

- Control Valve for Steering

- Hitch Group

- Hydraulic Pump

- Steering Cylinders

- Steering Gear and Follow-Up Linkage

Cat 950 Loader Air Brakes

- Specifications

- Air Chamber and Master Cylinder

- Air Compressor (Bendix-Westinghouse)

- Air Compressor (Clayton Dewandre)

- Control Valve for Emergency and Parking Brake

- Emergency and Parking Brake Linkage Adjustment

- Emergency and Parking Brake Chambe

- Parking Brake Lever

- Pressure Switches

- Safety Valve

- Wheel Brake Assembly (Disc)

- Wheel Brake (Shoe)

- Systems Operation

- Testing & Adjusting

Cat 950 Loader Lubrication Guide

- Safety

- Walk-Around Checks

- Fuel and Lubricant Specifications

- Lubrication and Maintenance Chart

- Every 10 Service Hours or Daily

- Every 100 Service Hours or 2 Weeks

- Every 250 Service Hours or Monthly

- Every 500 Service Hours or 3 Months

- Every 1000 Service Hours or 6 Months

- Every 2000 Service Hours or 1 Year

- When Required

- Wiring Diagrams

- Refill Capacities

- Serial Number Locations

Flow Meter Tee Test Procedure II

- Equipment Installation

- Machine Warm-up

- System Test (Chart A)

- Record Basic Test Values

- Troubleshooting

- Pump Test (Chart B)

- Pump Test for Aeration and Cavitation

- Troubleshooting

- Blocked Cylinder Tests (Chart C)

- Right Hand Cylinders Blocked

- Troubleshooting

Reviews

There are no reviews yet.